[CASTING SIMULATION] Utilize the CT Data for ADSTEFAN ADPT through VGSTUDIO MAX

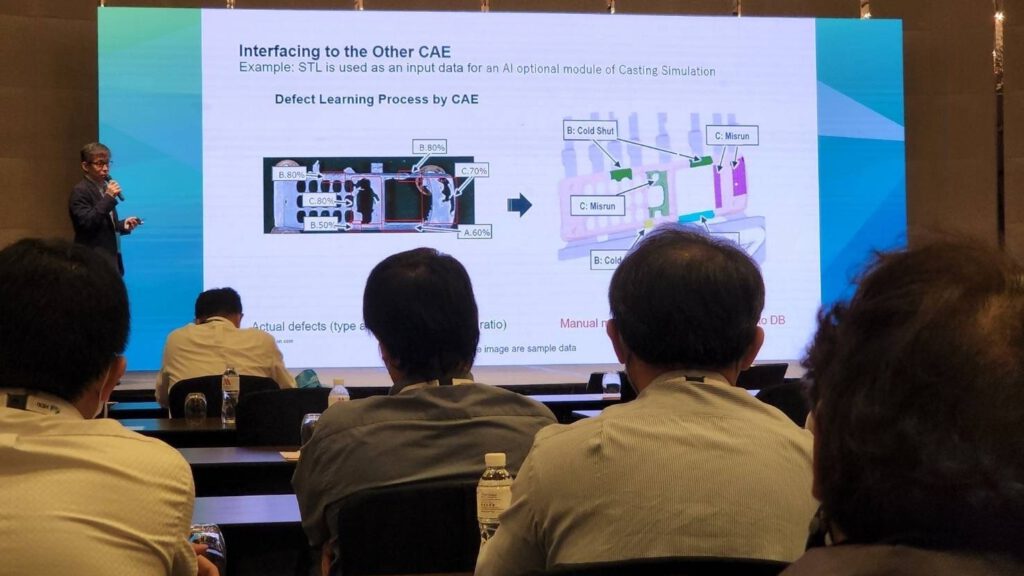

This content is a part of the presentation that we made on 19 July 2022 at Bangkok Marriott Hotel Sukhumvit during a conference organized by Hexagon Manufacturing Intelligence.

Summary

- CT scanned 3D data can be further utilized through VGSTUDIO MAX, Volume Graphics CT analysis and visualization software.

- The strong Surface Determination algorithm in VGSTUDIO MAX helps to export a high quality and useful 3D data from CT scanning system.

- VGSTUDIO MAX can be the interface between CT inspection data and the other software such as Casting CAE and Q-DAS

What is ADSTEFAN ADPT?

ADSTEFAN is a casting simulation software developed by an industry-academia collaborative project launched at Tohoku University led by Professor Niyama and Professor Anzai. The parameter (Niyama Criterion) consisting of temperature gradient and cooling rate by Professor Niyama is world-famous and used in many other CAE software programs. ADSTEFAN is widely used by many users especially in Japan under the support of Hitachi Industry & Control Solutions, Ltd.

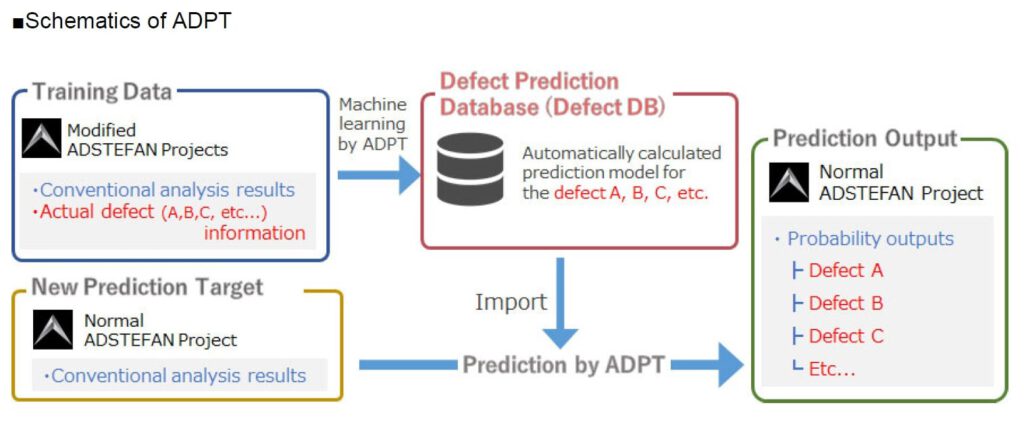

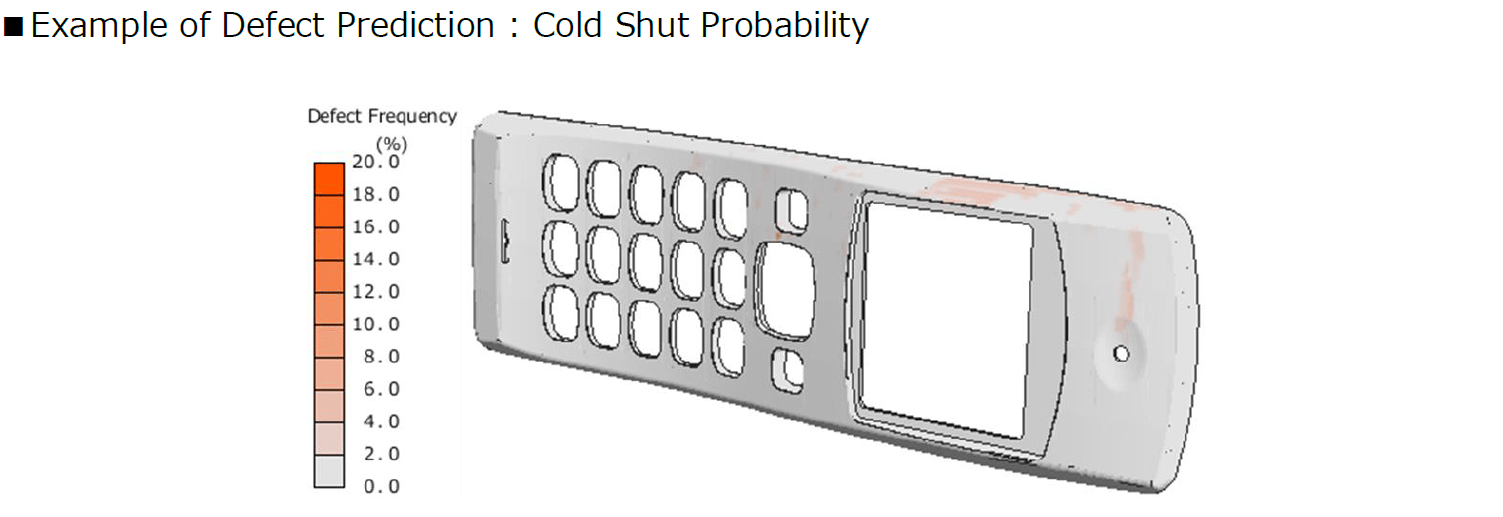

ADSTEFAN’s defect prediction tool (ADPT, Advanced Defect Prediction Tool) uses both actual casting defect information and simulation analysis results as “teaching data” and builds a defect prediction database using machine learning then outputs the probability of the defects considering the actual shop floor environment.

The prediction model is directly linked to the actual defect information therefore it allows to reduce troublesome “fitting” effort, and expects a more accurate simulation for a new design and products.

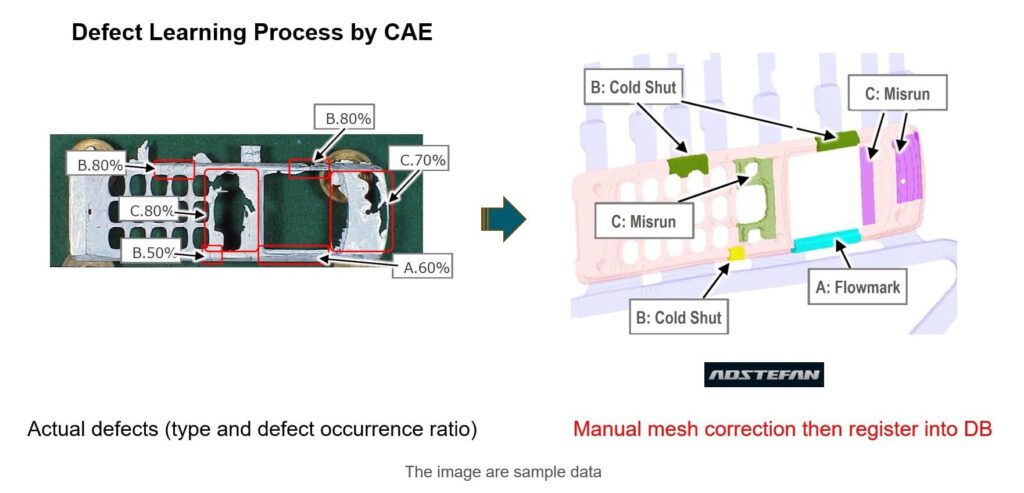

Prior to using ADPT, the actual casting defect information obtained by inspecting systems such as CT or X-ray needs to be prepared. The required information is defect types as well as its occurrence ratio by each location. The defect information registration process is a bit time consuming process as it requires manual mesh modifications especially registering the defect like shrinkage porosity which are usually located deep inside the mesh model.

Using CT Data for ADSTEFAN ADPT Input

1. Various CT Data Extruction by VGSTUDIO MAX:

3D data through CT scanning can be exported by VGSTUDIO MAX thanks to its strong Surface Determination algorithm which defines the product borderline in subvoxel accuracy which maintains 3D data quality. The 3D data exporting is available not only for the product geometry but also for only the internal defects. The exported 3D data is a solid 3D model unlike the surface model from point cloud data captured by 3D scanners.

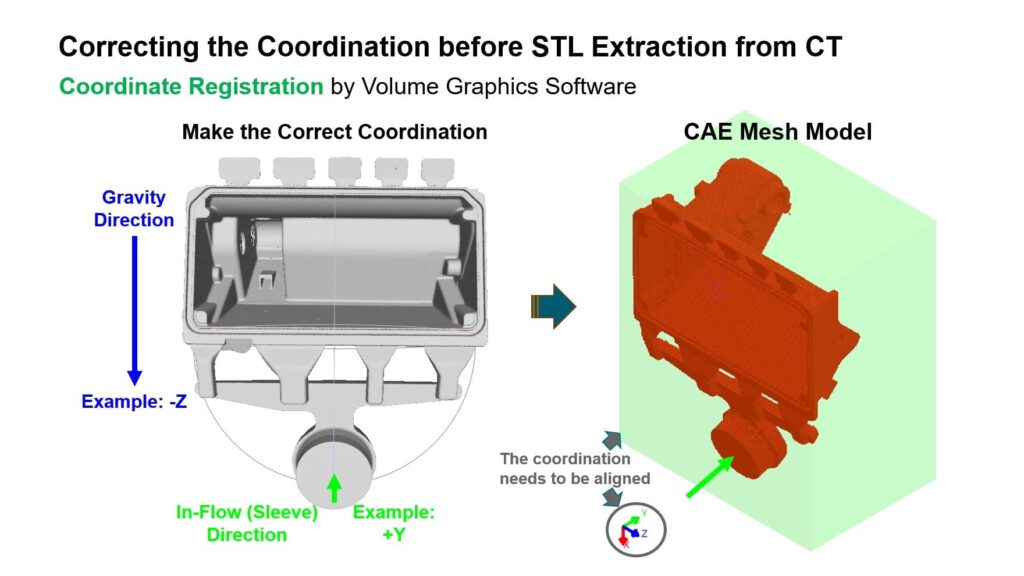

2. Correcting the Coordination before the 3D Data Exporting:

Maybe it’s a good idea to align the coordination before 3D data exporting. A casting model for example, the gravity direction should be aligned with one of the coordination axis and the other axis should be along with the inflow direction. VGSTUDIO MAX has various methods for Coordinate Registration.

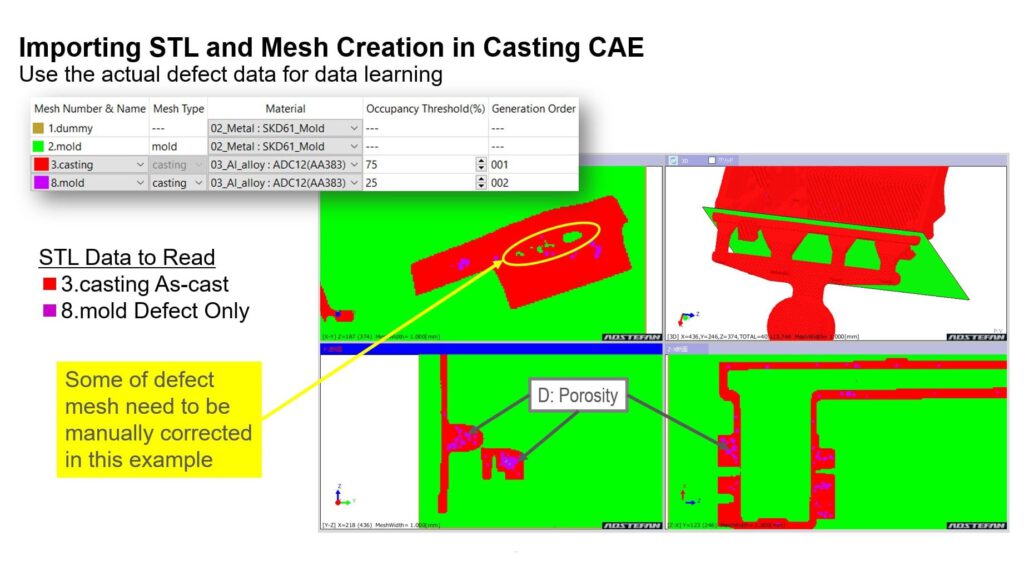

3. Importing the Defect 3D Data to ADSTEFAN:

The exported defect 3D data in STL format by VGSTUDIO MAX can be imported to ADSTEFAN together with the as-cast model data. The different mesh are easily generated by using the different STL data which will save a great amount of time for the mesh correction. Then, in order for ADSTEFAN ADPT to learn the actual defect information, the type of defect and its occurrence ratio are to be registered to each defect mesh. But this process doesn’t take time as long as the data is ready.

If you have any questions, please feel free to contact us.

Contact:

Robin Seino (Mobile Phone: 083 064 2112)

Wiphawee Sawetwiharee (Mobile Phone: 083 064 6976)