[NDT] Product Information : VGSTUDIO MAX 2025.3

Here are some exciting features of VGSTUDIO MAX 2025.3 for enhancing your Non-Destructive Testing

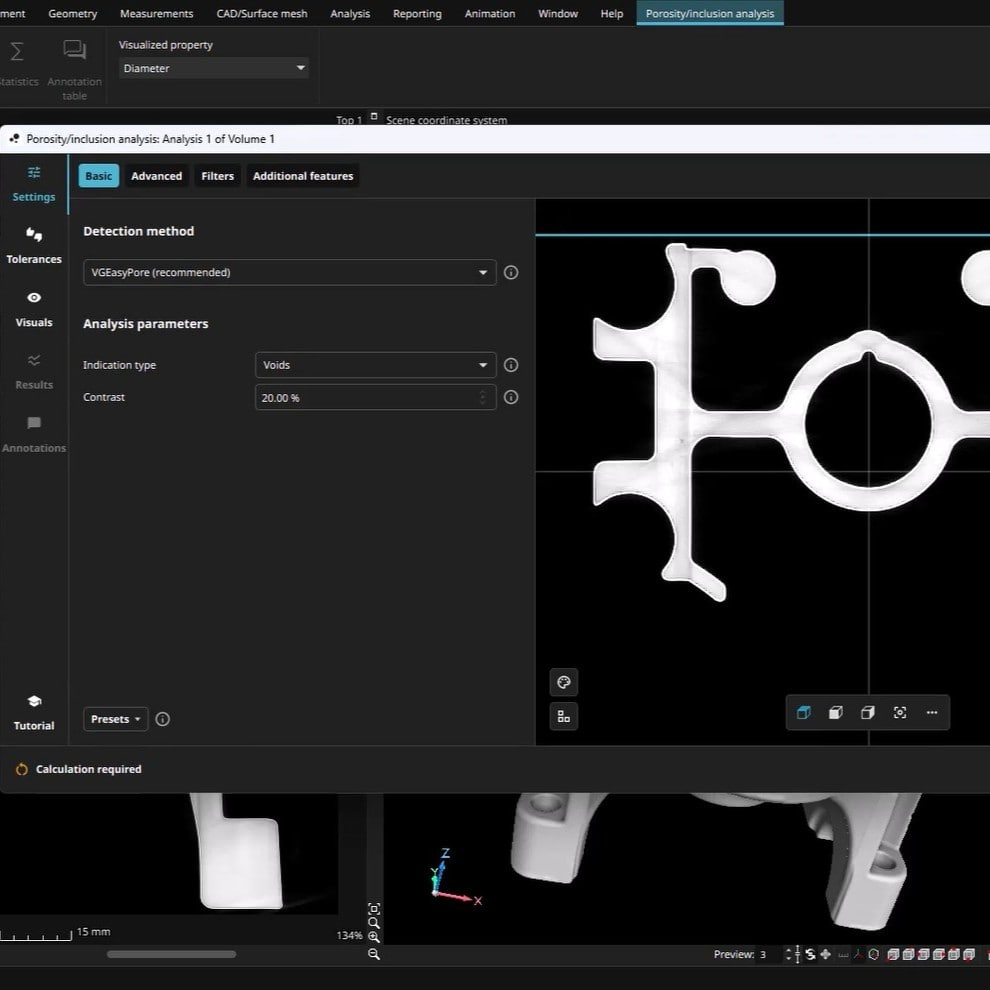

- Porosity/Inclusion Analysis: The user interface has been updated. The preview has been seamlessly integrated into the analysis window and also includes an interactive minimap that shows your current position in the analysis window. This makes navigation easier and ensures that you always have an overview of your component.

- Multipart coordinate measurement: The multipart coordinate measurement feature simplifies the handling of complex projects by allowing users to view, analyze, and edit measurement plans for multiple parts in one central location.

- Create and modify dimensions directly in the 3D view: With the dimensioning dialog open, you can now easily create and adjust dimensioning features by dragging and dropping the measurement lines directly in the 3D view, allowing for easy placement in the correct direction and optimal visibility.

- And a lot more…

What’s New in VGSTUDIO MAX 2025.3

[New] Porosity/Inclusion Analysis

Material analysis at the highest level

The latest release of VGSTUDIO MAX 2025.3, the user interface for porosity/inclusion analysis has been completely redesigned. The all important settings are now summarized at a glance, while advanced options are easily accessible on separate tabs.

The preview has been seamlessly integrated into the analysis window and also includes an interactive minimap that shows your current position in the analysis window. This makes navigation easier and ensures that you always have an overview of your component.

The new features for the Porosity & Inclusion analysis are summarized as follows :

- Completely Redesigned Analysis Setup Interface: A new, streamlined interface consolidates all primary settings onto a single page. Advanced options have been separated into distinct tabs, enhancing both the convenience and speed of operation.

- Unified Analysis Module: The entire workflow for porosity and inclusion analysis has been integrated into a single, cohesive module. Fewer clicks, more overview, maximum control. For the first time, all porosity/inclusion analysis procedures have been brought together in a single solution. This eliminates the need to switch between different windows, saving time and providing greater control over the analysis process.

- Interactive Preview and Minimap: The analysis setup window now features a live preview of the results, complete with an interactive minimap. This allows for a better overview and simplifies navigation within the dataset.

- Improved Visualization and Data Management: The system for displaying and managing data has been enhanced to support more precise and systematic analysis workflows.

These features significantly improve the efficiency and usability of the porosity and inclusion analysis capabilities compared to previous versions.

Summary

- Intuitive design: All important settings are immediately visible, while advanced options are clearly organized on separate tabs.

- Efficient workflow: For the first time, all porosity/inclusion analysis procedures have been brought together in a single solution. This allows for direct access to the core functions and eliminates the need to switch between different dialogs, saving valuable time.

- Everything at a glance: The new preview in the analysis dialog combines all important information and makes navigation easier thanks to the interactive minimap.

VGSTUDIO MAX Add-on Modules

VGSTUDIO MAX allows customers to choose from a variety of add-on modules for material analysis, geometry analysis, simulation and CT reconstruction according to the analysis needs.

Geometry Analysis

This category of modules specializes in high-precision measurement, comparison, and inspection to verify that products meet design specifications. Ensure quality at every stage of the manufacturing process and reduce rework.

- Coordinate Measurement: Directly measure and evaluate dimensions and Geometric Dimensioning and Tolerancing (GD&T) from CT data. This module provides a comprehensive suite of metrology tools that work on the native voxel data, enabling highly accurate measurements without the need for surface determination or triangulation, making it a powerful solution for quality control.

- Nominal/Actual Comparison: Three-dimensionally compare CAD data with CT scan data and visualize geometric deviations with intuitive color maps. This is essential for first article inspection, tool validation, and identifying manufacturing trends. The module allows for a full-field comparison, highlighting any warpage, shrinkage, or other geometric discrepancies across the entire part.

- Wall Thickness Analysis: Non-destructively analyze the wall thickness of an entire part and identify areas that deviate from the design. Using a sphere-based method, it accurately measures thickness even in complex geometries like castings or injection-molded parts. This helps ensure structural integrity and prevent potential failure points caused by walls that are too thin or too thick.

- Manufacturing Geometry Correction: Corrects tooling, mold data, or 3D printing models based on the deviation analysis between a first-off part and the nominal CAD data. It automatically compensates for predictable manufacturing effects like warpage and shrinkage, enabling the production of dimensionally accurate parts much faster and with fewer iteration loops.

- CAD Import: Directly import native data from major CAD systems like CATIA, Creo, NX, and SOLIDWORKS, as well as standard formats. This ensures that all geometric information and product structure data are transferred without translation errors, providing a solid foundation for comparison and measurement tasks. It streamlines the workflow by eliminating cumbersome data conversion steps.

- PMI Extension for CAD Import: Read Product and Manufacturing Information (PMI) directly from CAD data to assist in automating measurement plans. This includes GD&T, annotations, and dimensional tolerances embedded in the 3D model. By using this information, inspection plans can be created much more efficiently, reducing manual input and ensuring that inspections are performed exactly as specified by the design engineer.

- Reverse Engineering: Recreate CAD models from CT data by extracting high-precision surface determined data through VGSTUDIO MAX. This module provides a comprehensive toolset for generating NURBS surfaces from the voxel or mesh data, which can then be exported in standard CAD formats like STEP or IGES. It is ideal for creating CAD models of legacy parts, competitors’ products, or for as-built design modifications.

Material Analysis

Analyze the internal structure of materials at a micro-level to clarify their properties. This enables a deeper understanding of product performance and reliability, leading to material development and quality improvement.

- Porosity/Inclusion Analysis: Detect and analyze internal defects such as porosity, voids, or inclusions, and evaluate them based on industry standards (e.g., BDG P 203). The module provides detailed statistics on defect size, shape, and location, which is critical for assessing the quality of castings and ensuring the reliability of safety-critical components in automotive and aerospace applications.

- Fiber Composite Material Analysis: Analyze the orientation, volume fraction, and other key properties of fibers in composite materials such as fiber-reinforced plastics (FRP). Understanding the local fiber orientation is crucial for accurately predicting the mechanical behavior and performance of composite parts. This module provides the detailed data needed for advanced structural simulations.

- Foam/Powder Analysis: Quantitatively evaluate the cell or particle structures of materials like metal foams, porous materials, and powder sinters. It calculates statistics on cell sizes, wall thicknesses, and strut orientations. This information is vital for understanding the mechanical, thermal, and acoustic properties of these complex materials, enabling better design and process control.

- Battery Analysis: Analyze the detailed internal structure of battery cells to evaluate quality and safety. This module provides specialized tools for measuring critical parameters like anode overhang, electrode curvature, and particle distribution. It helps detect manufacturing defects such as delamination or foreign particles, which is essential for improving battery performance and preventing failures.

- Digital Volume Correlation Compare CT data of a part before and after deformation (e.g., from an in-situ load test) to visualize and quantify internal strain and displacement fields. This powerful technique provides a full 3D view of how a material behaves under stress, revealing local strain concentrations and deformation mechanisms that cannot be observed with external measurement methods.

Simulation

Provides functionality for simulating physical phenomena and correcting data to solve manufacturing issues, significantly contributing to the reduction of prototype iterations and shortening development time.

- Structural Mechanics Simulation: Perform stress and strain simulations directly on the voxel data from a CT scan. This approach uses the actual manufactured geometry, including any internal defects like pores, providing a highly realistic prediction of how a part will behave under load. It eliminates the need for mesh generation and allows for more accurate performance validation than simulations based on idealized CAD models.

- Transport Phenomena Simulation: Simulate flow, diffusion, and thermal or electrical conductivity in porous or multi-material components. By working directly on the scanned microstructure, this module can accurately calculate properties like permeability, tortuousity, and effective conductivity. This is invaluable for designing filters, heat exchangers, or fuel cell components.

- Fixture Simulation: Simulate the deformation of a part when it is clamped in a fixture. This allows for the virtual alignment of a free-state scan to its clamped condition, improving the accuracy of metrological comparisons between the scan and the CAD model. It helps to differentiate between manufacturing deviations and deformations caused by the measurement setup.

- Volume Meshing: Create high-quality tetrahedral volume meshes from your CT scans for use in external FEM software. The advanced meshing algorithms can create meshes from complex, subvoxel-accurate surfaces of your scanned object, including internal structures. This bridges the gap between CT data and third-party simulation workflows like FEA or CFD.

CT Reconstruction

Provides specialized modules for generating high-quality 3D volume data from the 2D projection images acquired by a CT scanner, forming the foundation for all subsequent analyses.

- CT Reconstruction: Reconstruct high-quality 3D volume data sets from the 2D projection images generated by a CT scanner. This module offers advanced algorithms for artifact reduction, such as beam hardening correction and ring artifact removal, resulting in clearer and more accurate data for subsequent analysis. It provides the flexibility to optimize reconstruction parameters for the best possible image quality.

Artificial Intelligence

Provides specialized modules that leverage AI and deep learning to automate complex and time-consuming tasks, such as the segmentation of intricate structures.

- Deep Segmentation: Efficiently perform segmentation of complex materials and structures using AI (deep learning). Users can train a neural network on a small, manually segmented region to automate the segmentation of the entire dataset. This is particularly powerful for multi-material assemblies, fiber composites, or porous materials where traditional thresholding methods fail.

- GelSight Integration: Import and analyze high-resolution surface topography and texture data acquired with GelSight sensors. This module allows for the combination of internal 3D structure from a CT scan with highly detailed surface information. This integrated approach enables a comprehensive analysis of both surface features, such as roughness or micro-defects, and internal characteristics in a single coordinate system.

VGSTUDIO MAX add-on module can be installed as a pre-configured package together with Basic Edition according to the application field. Alternatively, customers can purchase the add-on module individually or as a bundle later after having VGSTUDIO MAX Basic Edition license.

| Add-on Modules | VGSTUDIO MAX Package | |||||||

|---|---|---|---|---|---|---|---|---|

| Geometry | Material | Cast & Mold | Composites & Plastic | Additive Manufacturing | Battery | Universal | Ultimate | |

| Coordinate Measurement | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Nominal/Actual Comparison | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Wall Thickness Analysis | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Porosity/Inclusion Analysis | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Fiber Composite Material Analysis | ✔ | ✔ | ✔ | ✔ | ||||

| Foam/Powder Analysis | ✔ | ✔ | ✔ | ✔ | ||||

| Battery Analysis | ✔ | ✔ | ||||||

| Manufacturing Geometry Correction | ✔ | ✔ | ||||||

| Volume Meshing | ✔ | ✔ | ||||||

| Structural Mechanics Simulation | ✔ | ✔ | ||||||

| Transport Phenomena Simulation | ✔ | |||||||

| Reverse Engineering | ✔ | ✔ | ||||||

| Digital Volume Correlation | ✔ | ✔ | ||||||

| CAD Import* | ✔ | |||||||

| CAD Import with PMI** | ✔ | |||||||

| CT Reconstruction | ✔ | ✔ | ||||||

| Deep Segmentation | ✔ | ✔ | ||||||

*CAD Translation Technology supplied by Tech Soft 3D

Feature Comparison by Software Editions

Even the basic edition of VGSTUDIO MAX without add-on modules, it’s clearly different from VGSTUDIO. VGSTUDIO MAX is a more comprehensive, high-performance, advanced version that expands the functionality of VGSTUDIO.

| Features | VGSTUDIO | VGSTUDIO MAX |

|---|---|---|

| Surface determination | n/a | Isovalue based, Advanced (classic), Advanced (multi-material) (with Coordinate Measurement module) |

| Visualization | 3D visualization of even very large CT data sets with almost no limit on data volume | |

| Segmentation | n/a | Separate data sets into individual parts (Regions of Interest or ROIs) that may consist of different components, materials, etc. by using manual selection and drawing tools as well as semi-automated tools |

| Analysis | Data quality analysis according to the ASTM E 1695 standard to monitor the CT scan quality over time | Data quality analysis according to the ASTM E 1695 standard to monitor the CT scan quality over time; Text recognition to read out object identifiers such as cavity markers from CT scans; Gray value analysis |

| Automation | n/a | Automate the analysis of single data sets or a group of data sets with macros |

| Registration (Alignment) | Simple registration; Simple 3-2-1 registration |

Simple registration; Simple 3-2-1 registration; Best fit registration; 3-2-1 registration; Feature-based registration; Sequential registration, etc. |

| Measurement instruments | Distance, polyline length, and angle measurement instruments | Distance, polyline length, and angle measurement instruments with capability of import of instrument template; Full GD&T functionality (with Coordinate Measurement module) |

| Add-on modules | CT reconstruction only | All available VG add-on modules |

| Data import | ||

| Images | Import data from most major industrial CT systems; Import standard image formats (such as .bmp, .jpg, .jp2, .raw, .tif) as well as DICOM and DICONDE data | |

| CAD models | n/a | .stp, .step, .igs, .iges, .catpart, .catproduct, .prt, .asm, .jt, .model, .dlv, .exp, .par, .sldprt, .sldasm |

| Surface meshes | *.stl, *.STL, *.obj, *.ply | |

| Point clouds | n/a | .txt, .csv, .asc, .xyz, .lsproj, .fls, .fws |

| Integration meshes | n/a | .pat, .bdf, .emv |

| Data export | ||

| Image stack files | Import standard image formats (such as .bmp, .jpg, .jp2, .raw, .tif, .gz, .dcm) | |

| Volume file formats | .hdr, .raw, .gz, .hdf as well as multiple volumes incl. .raw, .wmv, .avi, .bmp, etc. | |

| CAD models | n/a | .stp (with add-on module) |

| Surface meshes | *.txt, *.off,*.stl, *.wrl, *.wrz, *.obj, *.ply | |

| Tetrahedral meshes | n/a | .pat, .inp (with add-on module) |

| Others | n/a | MAGMA/Volume Graphics file exchange format, Digimat/Volume Graphics file exchange format, Q-DAS files |

| Images & videos | Standard image and video formats (such as .jpg, .jpeg, .avi, .wmv, .tiff, etc.) | |

VGTRAINER

VGTRAINER is model training software that utilizes AI (deep learning) and specializes in the segmentation of industrial CT data. For example, the aforementioned AI-based add-on module, “Deep Segmentation,” is realized by integrating VGTRAINER with VGSTUDIO MAX (or VGinLINE).

Key Features and Functions

- No-Code AI Model Generation: AI models can be created using labeled training data, even without programming or AI expertise. Users simply upload trained CT data, and the AI automatically builds a segmentation model.

- On-Premises Support and Secure: Data security is ensured with a completely on-premise system, with no cloud dependency.

- Fast and Stable Segmentation for High-Throughput Environments: High-speed, highly reproducible segmentation is achieved, even for hundreds of CT data sets.

- Seamless Integration with VG Software: Trained models can be directly applied to the Deep Segmentation module in VGSTUDIO MAX or VGinLINE, enabling easy deployment to production lines and R&D environments.

- Retraining (Fine-Tuning): Existing deep learning models can be fine-tuned for similar new inspection tasks using a small number of CT data sets (e.g., 2-3). This is particularly useful when fine-tuning multiple production lines or equipment.

Free Viewer myVGL 2025.3

Customers can freely download a viewer software, myVGL 2025.3 to open the 3D project data which was created by VGSTUDIO or VGSTUDIO MAX. Not only rotating or moving the CT scan model to evaluate at any angle or cross section but some simple measurement tools are available in the software. Please refer to our other article for knowing how to use myVGL.>>Learning myVGL Basics within 10 minutes

For more information about the VGSTUDIO MAX product

For more information, please download the catalog of VGSTUDIO MAX

If you are looking for an effective CT data analysis, contact us for a consultation and more information.

Related Information:

Non Destructive Testing (Industrial X-ray CT System) Products